Meyer Sound - Research & Development

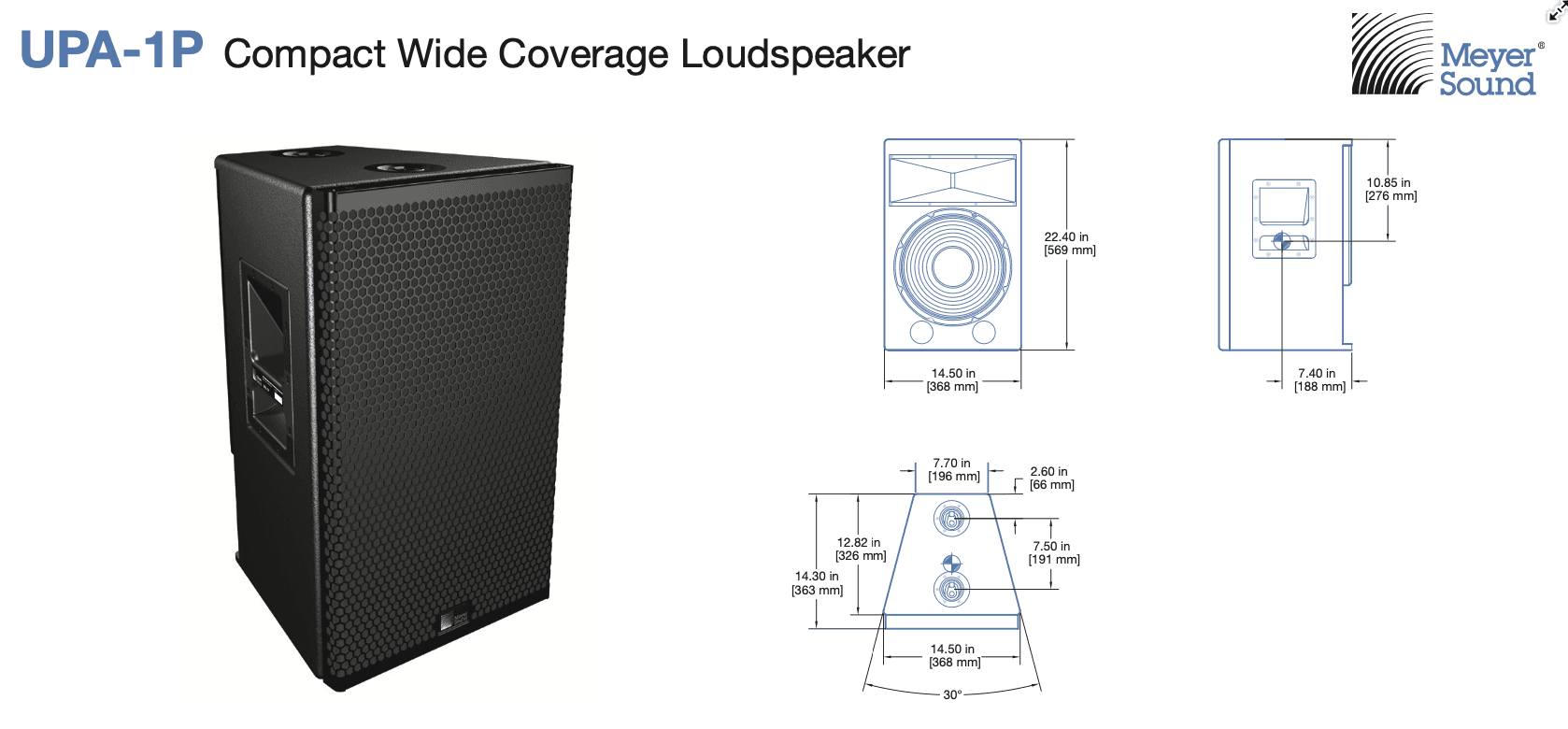

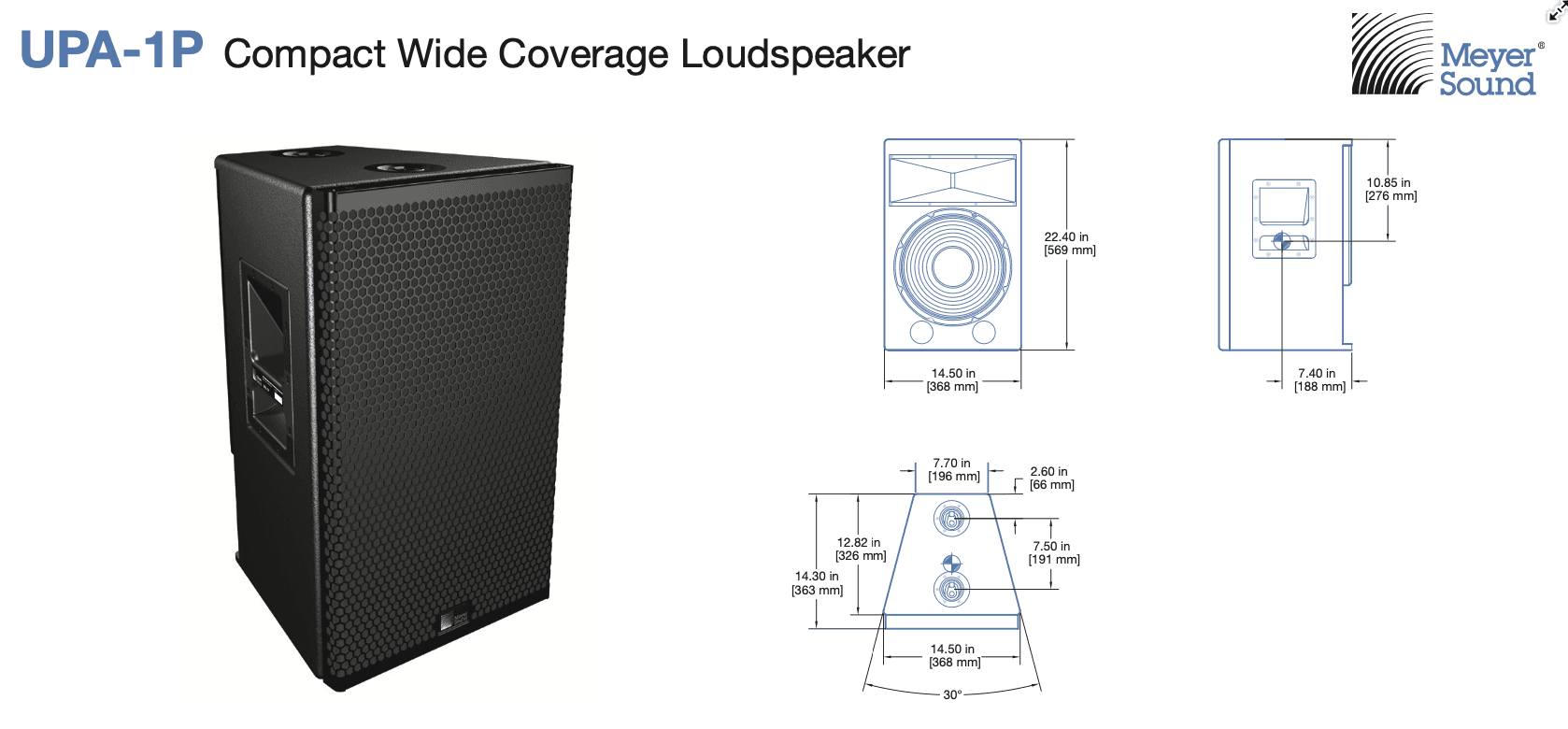

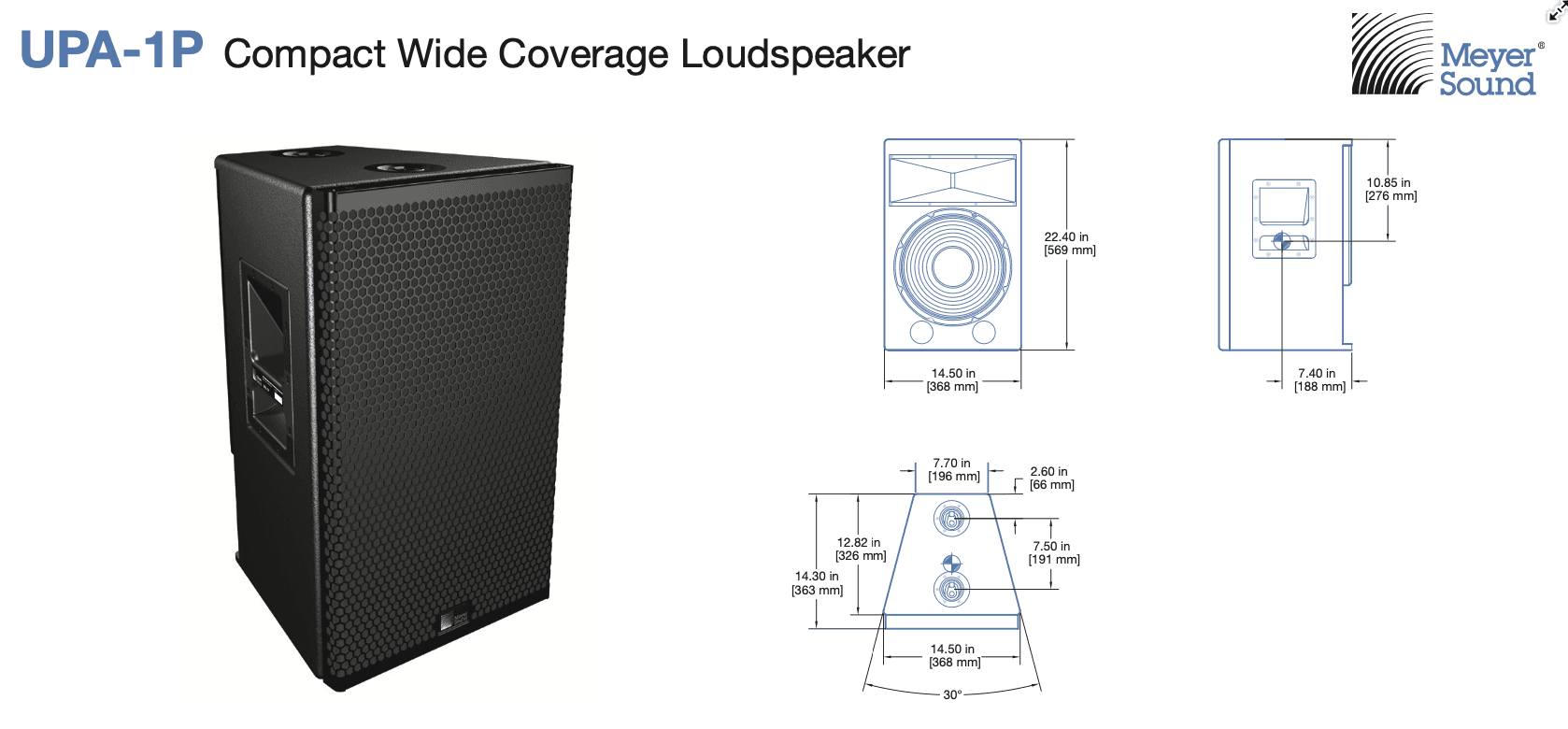

Within a small core of engineers, worked on self powered speaker analog circuit design, measurement and optimization for the following products – UPA-1P, UPA-2P, USW-1P, HM-1 and HM-1S, MSL-4, 750-P, X-10, UPM-1P, UPM-2P, UM-1P, UM-100P, MSL-6, PSW-6, DF-4, M3D, MM-4.

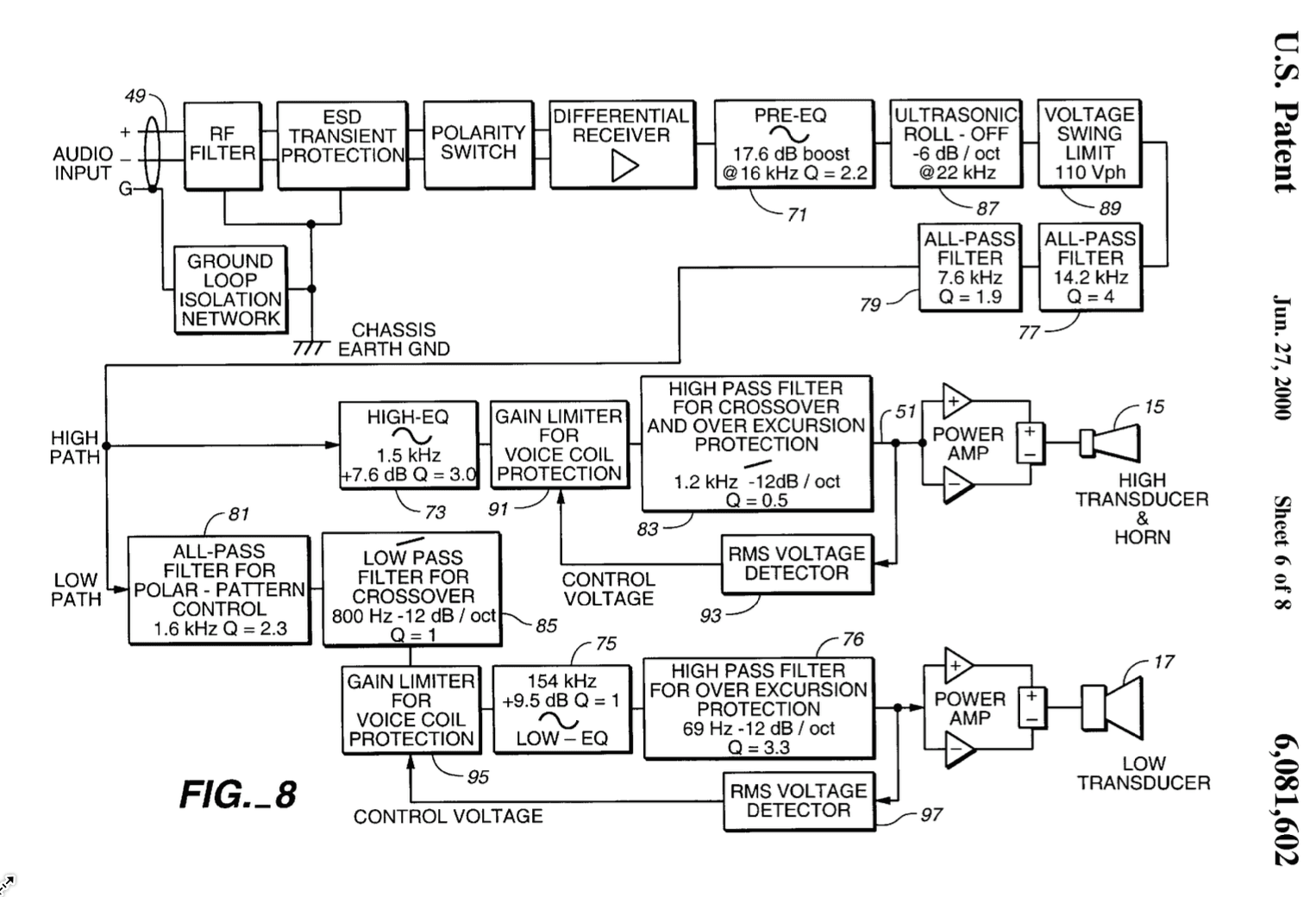

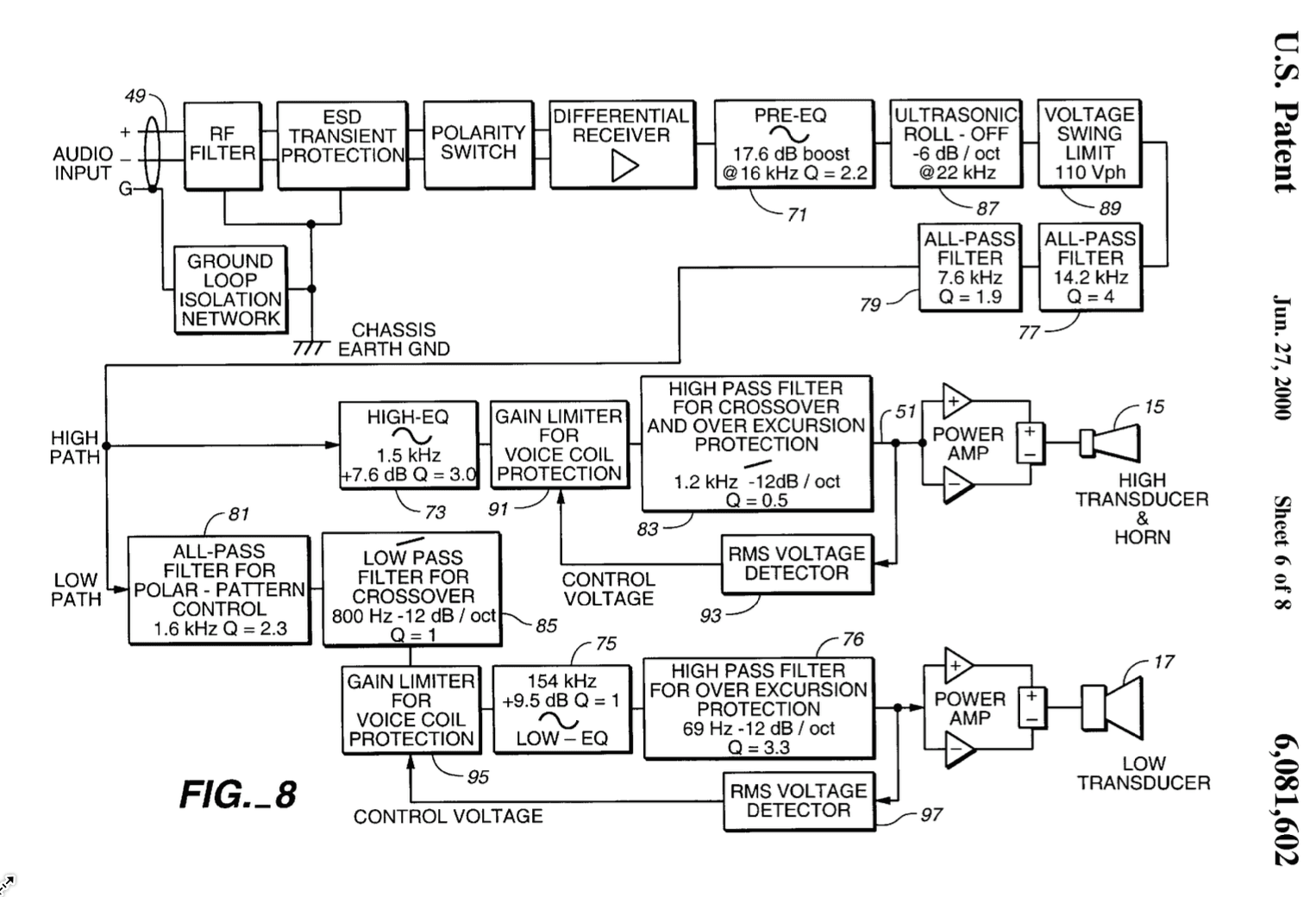

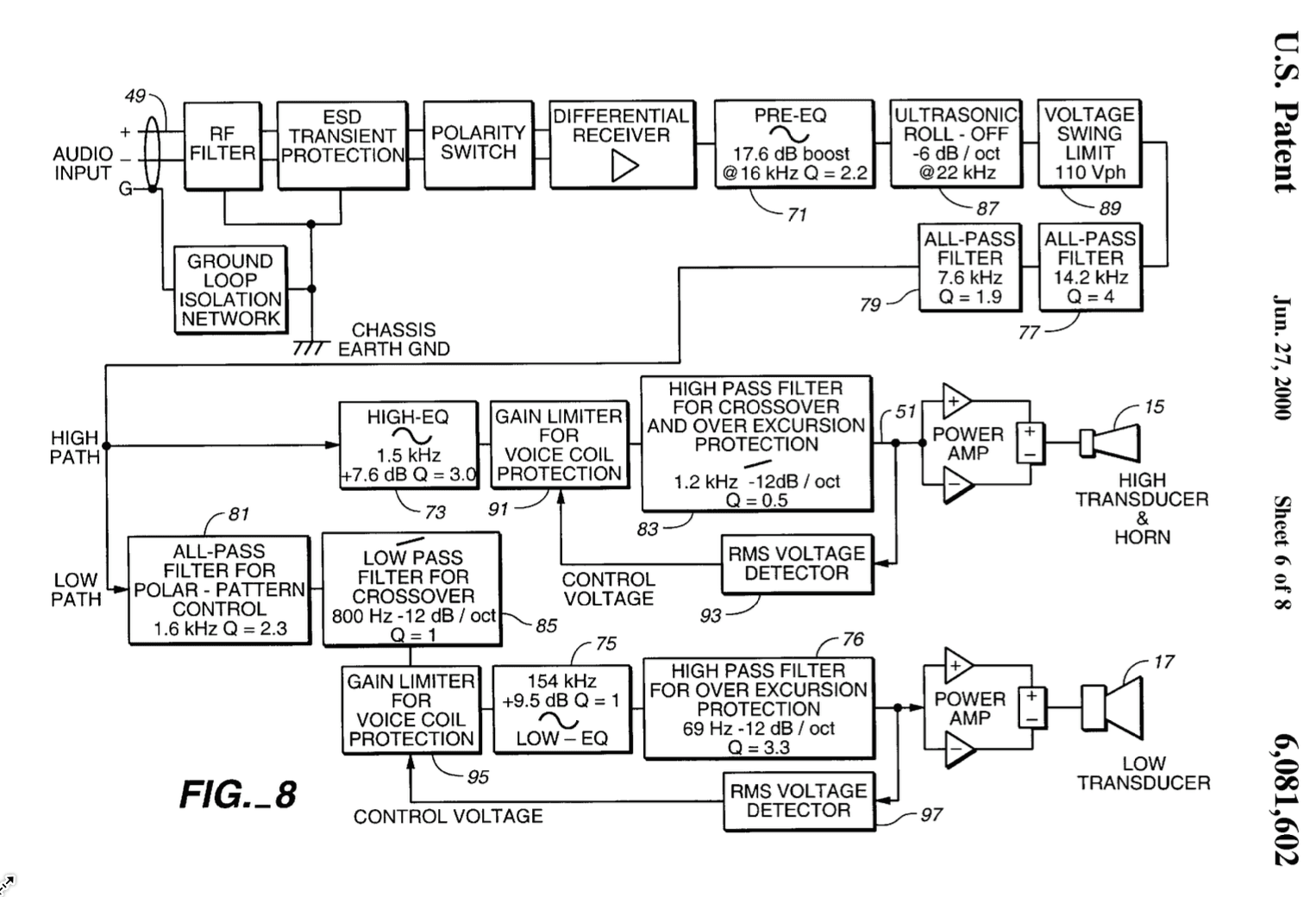

United States Patent for the UPA-1P:

ARRAYABLE TWO-WAY LOUDSPEAKER SYSTEM AND METHOD with fellow inventors John Meyer and Paul Kohut. US006081602A

The loudspeaker system and method of the present invention is principally concerned with the polar response of a loudspeaker in the horizontal plane, and with producing a horizontal polar response from a loudspeaker system that permits two or more loudspeaker systems having overlapping coverages to be easily arrayed without undesirable interactions between the acoustic outputs of the speaker systems. The loudspeaker system and method of the invention also concerns the need to achieve a common focalpoint about which each speaker can be arrayed. As used herein, the term “focal point,” sometimes referred to as an “acoustic center,” is understood to mean that point in space about which the speaker can be rotated to achieve a flat amplitude and flat phase response. A “focal axis” is that axis about which the speaker can be rotated to achieve a flat amplitude and flat phase response in the horizonal plane. Such determinations can be made by rotating the speaker relative to a fixed microphone, or rotating a microphone about a fixed speaker.

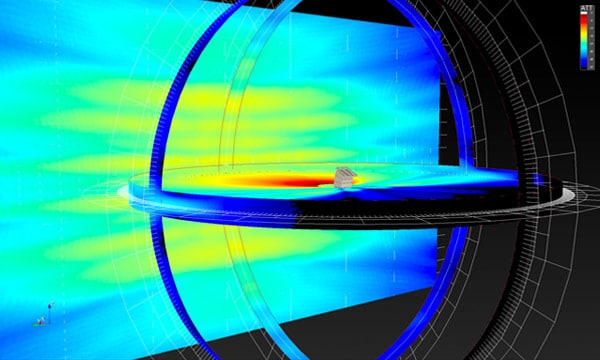

With Paul Kohut's guidance and mentorship, I designed the active filter system for the UPA-1P. Along with many other super interesting projects, I spent a huge amount of time inside this anechoic chamber, which sits in a very unassuming shed in the parking lot of Meyer Sound on San Pablo Avenue in Berkeley California:

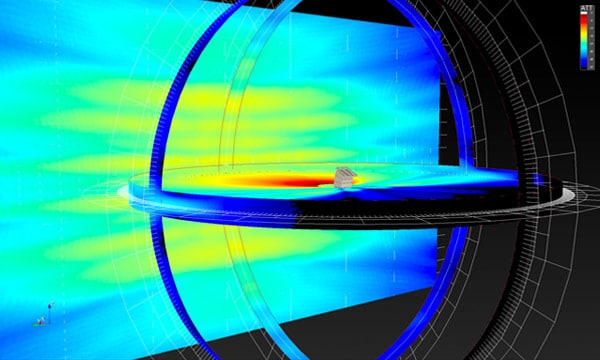

The chamber has a robot positioning arm which is capable of rotating heavy loudspeakers across all angles of azimuth and elevation, to a hundredth of a degree accuracy. In order to create the optimal active filter system for multiway loudspeakers, we would build the cabinets, waveguides and horns, and then measure each transducer separately, typically at 1-degree accuracy horizontally and vertically. These raw measurements would be imported into a MATLAB-based simulator to then work out the crossovers, parametric EQ filters, and allpass filters.

I also developed and maintained the Remote Monitoring Software (RMS) product and managed the product both internally and externally. I researched, implemented, and field tested an advanced large scale RMS deployment for the Tokyo Disney project, collaborating with Disney Engineering and Disney Imagineering.

I co-managed the transducer development and test group, working with both internal and external parties to specify, manufacture, test and maintain quality of all low and high frequency transducers used in production.

I worked with Solotech, Celin Dion’s sound company, to investigate and resolve the real world problems resulting in the destruction of MSL-4 high drivers through the creation and implementation of a fast acting peak limiter circuit.

Represented Meyer in AES standards committees, acting as Vice-Chair of the AESSC-SC-04-03 Subcommittee on Acoustics, Working Group on Loudspeaker Modelling and Measurement.

Represented Meyer as a technical liaison for both public and hosted events – speaking and presenting at audio conferences and seminars in North America, Europe, Australia, Asia and South America.

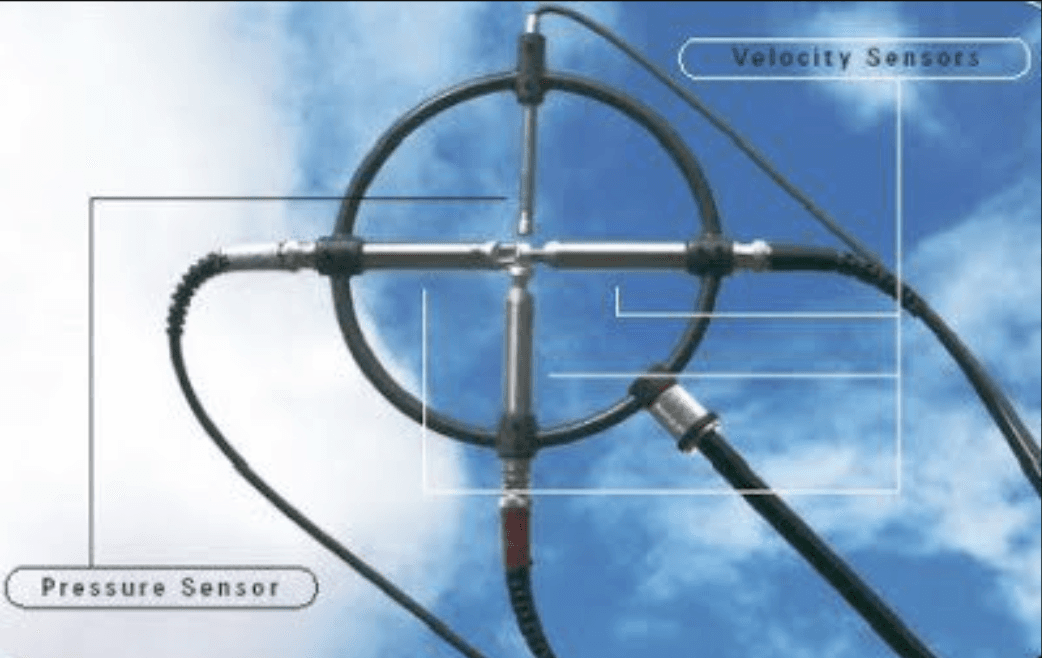

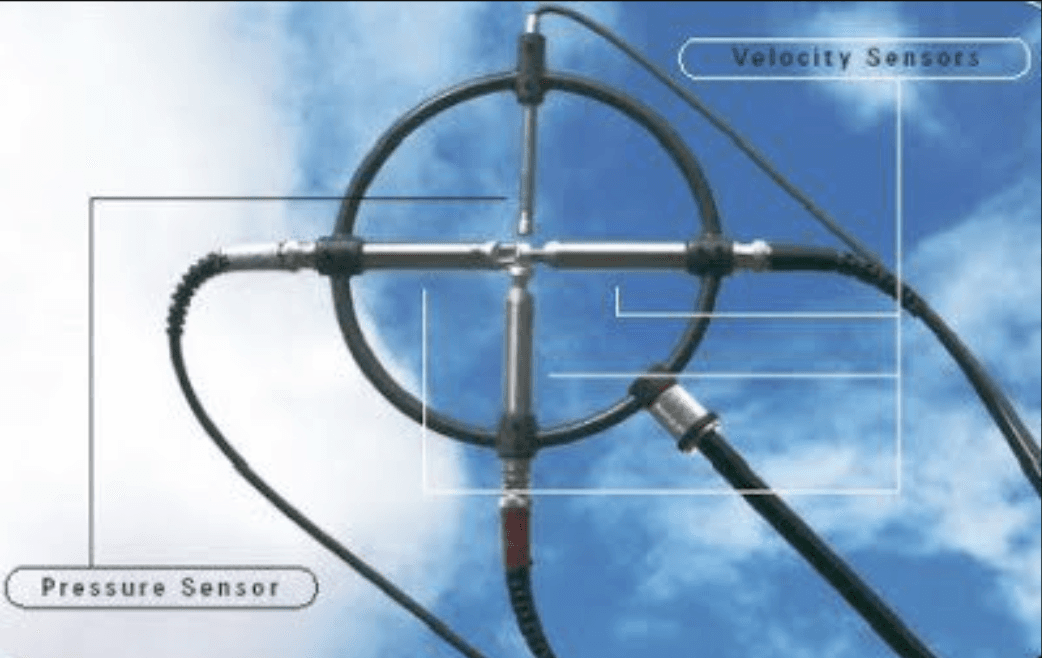

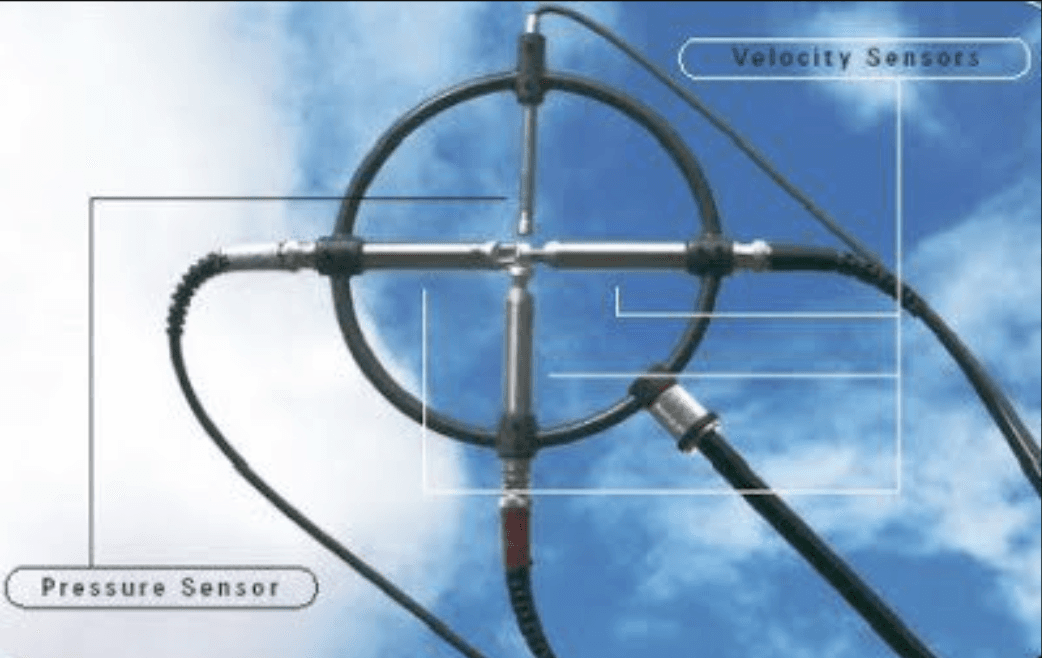

Developed a three-dimensional sound intensity probe utilizing a pressure sensor and three Microflown sound intensity probes – developed software acquisition and post processing system.

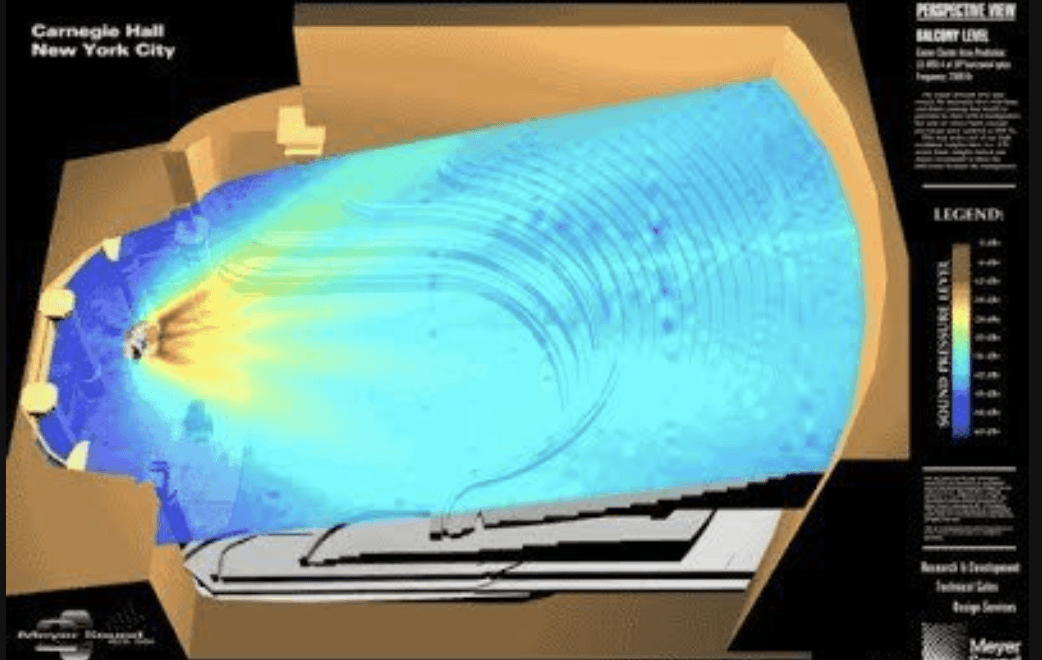

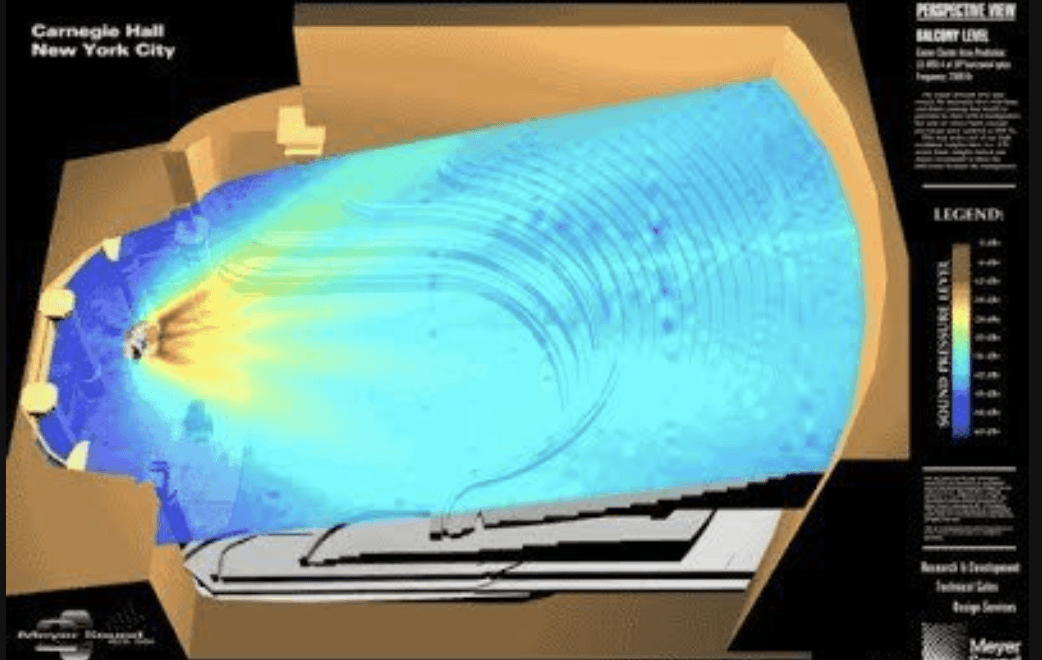

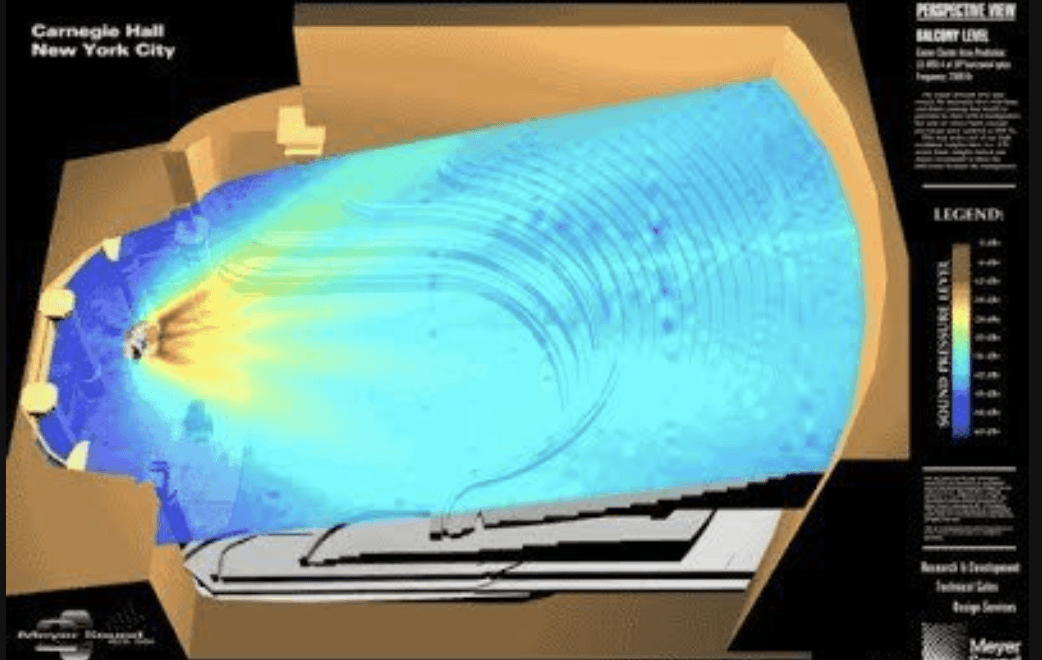

Performed acoustical analysis, post-processing and predictions for Carnegie Hall, system trialled and installed in 2000.

Performed acoustical analysis, post-processing and predictions for Royal Albert Hall (London, England) and Benaroya Concert Hall (Seattle, Washington, USA).

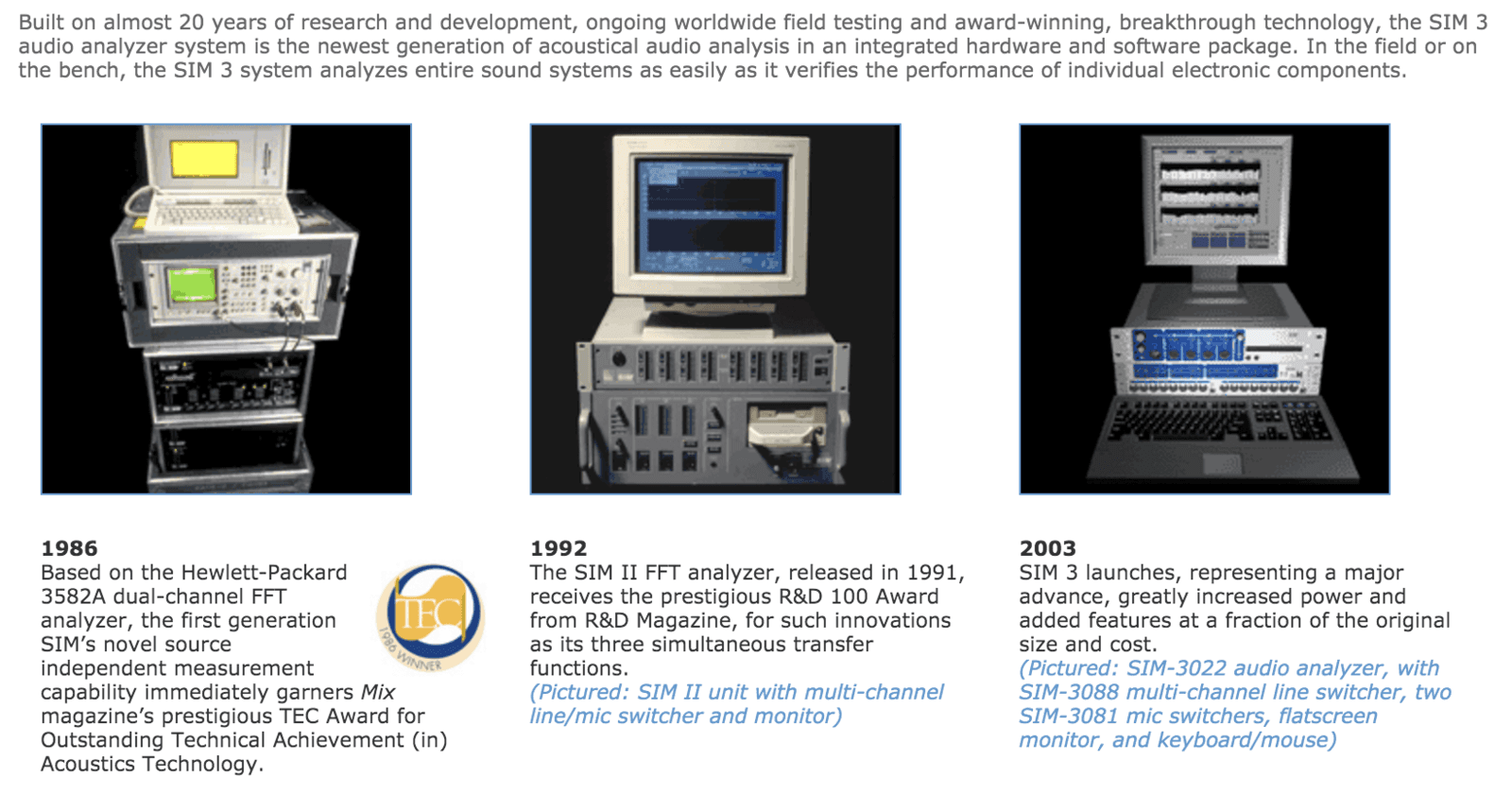

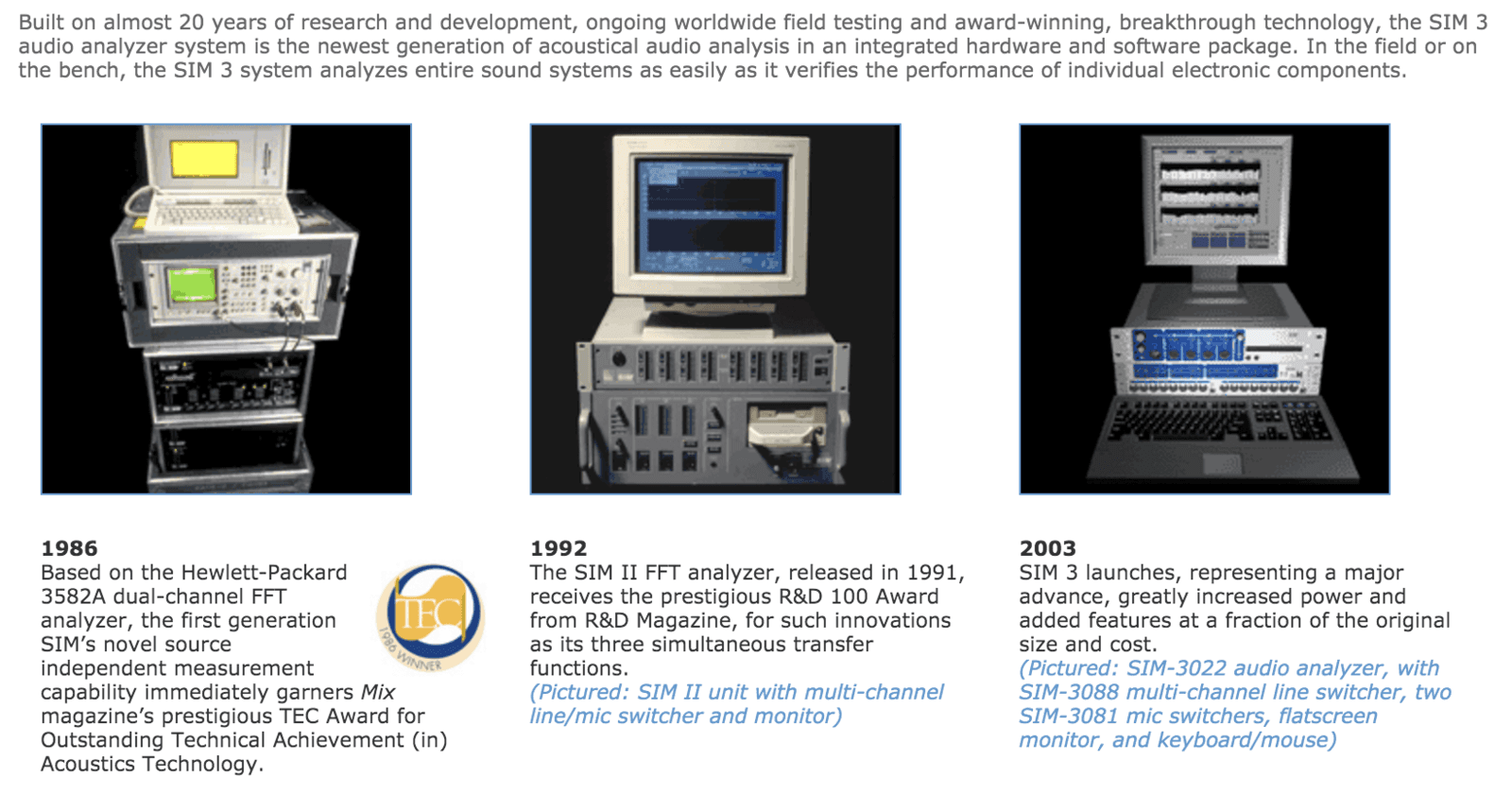

Wrote the embedded digital signal processing code for the third generation of the Meyer Sound Source Independent Measurement acoustical measurement and analysis system.

Authored and managed the creation of Meyer’s first release of acoustic data sets for the EASE electroacoustic prediction program.

Wrote numerous white papers and provided consultative review of application notes, datasheets, user manuals and other marketing materials.

Co-authored the first in-house versions of the Multipurpose Acoustic Prediction Program (MAPP) and verified its accuracy through numerous electroacoustic anechoic chamber measurements.

Developed the Meyer Matrix Processor, a high quality multi-channel rapid prototyping environment for the creation and real-time manipulation of digital audio signal processing systems.

Within a small core of engineers, worked on self powered speaker analog circuit design, measurement and optimization for the following products – UPA-1P, UPA-2P, USW-1P, HM-1 and HM-1S, MSL-4, 750-P, X-10, UPM-1P, UPM-2P, UM-1P, UM-100P, MSL-6, PSW-6, DF-4, M3D, MM-4.

United States Patent for the UPA-1P:

ARRAYABLE TWO-WAY LOUDSPEAKER SYSTEM AND METHOD with fellow inventors John Meyer and Paul Kohut. US006081602A

The loudspeaker system and method of the present invention is principally concerned with the polar response of a loudspeaker in the horizontal plane, and with producing a horizontal polar response from a loudspeaker system that permits two or more loudspeaker systems having overlapping coverages to be easily arrayed without undesirable interactions between the acoustic outputs of the speaker systems. The loudspeaker system and method of the invention also concerns the need to achieve a common focalpoint about which each speaker can be arrayed. As used herein, the term “focal point,” sometimes referred to as an “acoustic center,” is understood to mean that point in space about which the speaker can be rotated to achieve a flat amplitude and flat phase response. A “focal axis” is that axis about which the speaker can be rotated to achieve a flat amplitude and flat phase response in the horizonal plane. Such determinations can be made by rotating the speaker relative to a fixed microphone, or rotating a microphone about a fixed speaker.

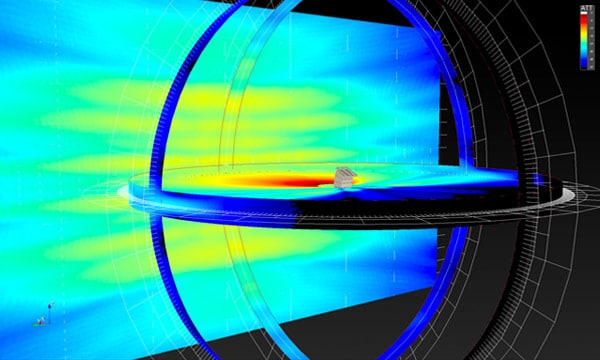

With Paul Kohut's guidance and mentorship, I designed the active filter system for the UPA-1P. Along with many other super interesting projects, I spent a huge amount of time inside this anechoic chamber, which sits in a very unassuming shed in the parking lot of Meyer Sound on San Pablo Avenue in Berkeley California:

The chamber has a robot positioning arm which is capable of rotating heavy loudspeakers across all angles of azimuth and elevation, to a hundredth of a degree accuracy. In order to create the optimal active filter system for multiway loudspeakers, we would build the cabinets, waveguides and horns, and then measure each transducer separately, typically at 1-degree accuracy horizontally and vertically. These raw measurements would be imported into a MATLAB-based simulator to then work out the crossovers, parametric EQ filters, and allpass filters.

I also developed and maintained the Remote Monitoring Software (RMS) product and managed the product both internally and externally. I researched, implemented, and field tested an advanced large scale RMS deployment for the Tokyo Disney project, collaborating with Disney Engineering and Disney Imagineering.

I co-managed the transducer development and test group, working with both internal and external parties to specify, manufacture, test and maintain quality of all low and high frequency transducers used in production.

I worked with Solotech, Celin Dion’s sound company, to investigate and resolve the real world problems resulting in the destruction of MSL-4 high drivers through the creation and implementation of a fast acting peak limiter circuit.

Represented Meyer in AES standards committees, acting as Vice-Chair of the AESSC-SC-04-03 Subcommittee on Acoustics, Working Group on Loudspeaker Modelling and Measurement.

Represented Meyer as a technical liaison for both public and hosted events – speaking and presenting at audio conferences and seminars in North America, Europe, Australia, Asia and South America.

Developed a three-dimensional sound intensity probe utilizing a pressure sensor and three Microflown sound intensity probes – developed software acquisition and post processing system.

Performed acoustical analysis, post-processing and predictions for Carnegie Hall, system trialled and installed in 2000.

Performed acoustical analysis, post-processing and predictions for Royal Albert Hall (London, England) and Benaroya Concert Hall (Seattle, Washington, USA).

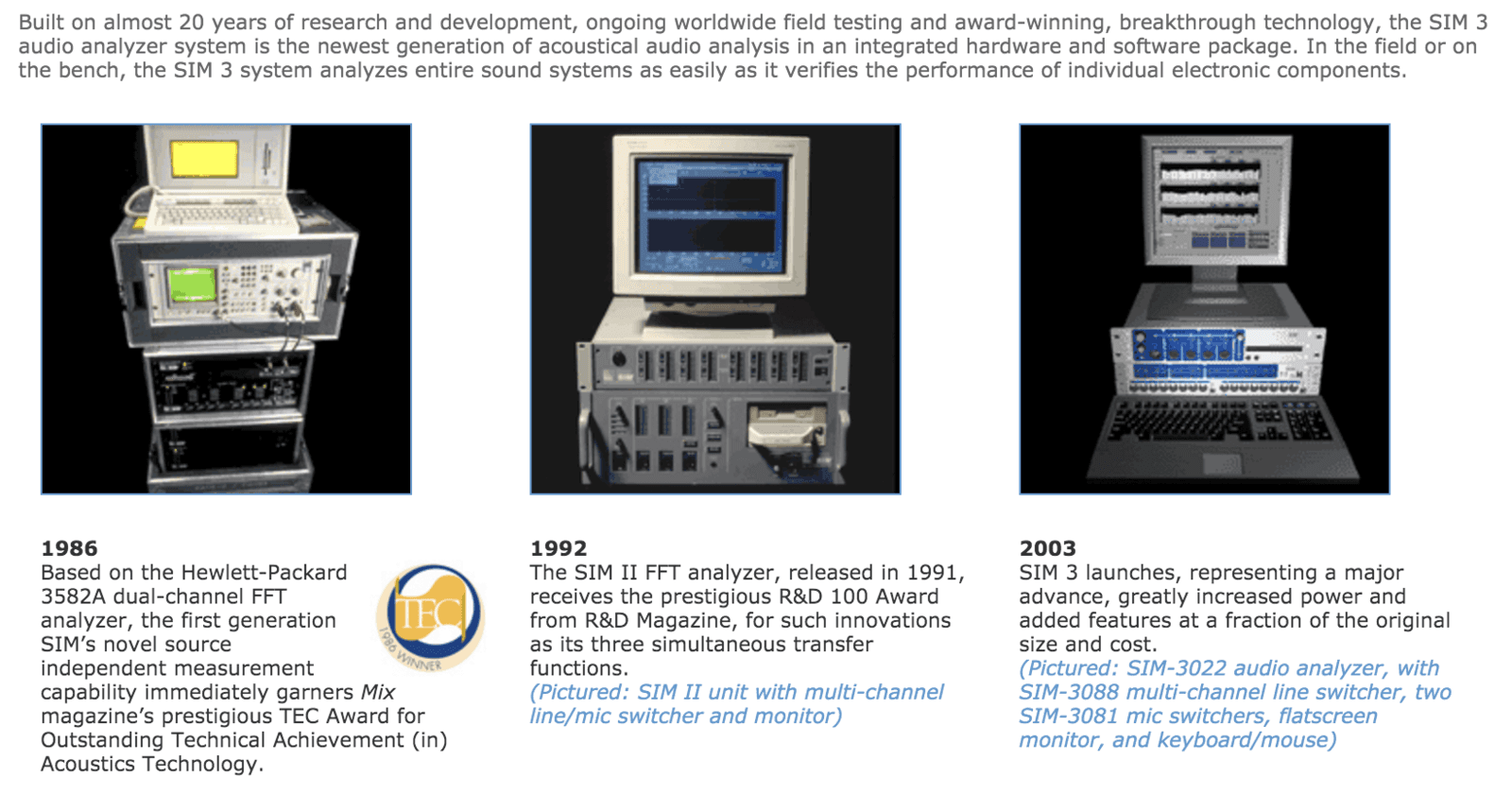

Wrote the embedded digital signal processing code for the third generation of the Meyer Sound Source Independent Measurement acoustical measurement and analysis system.

Authored and managed the creation of Meyer’s first release of acoustic data sets for the EASE electroacoustic prediction program.

Wrote numerous white papers and provided consultative review of application notes, datasheets, user manuals and other marketing materials.

Co-authored the first in-house versions of the Multipurpose Acoustic Prediction Program (MAPP) and verified its accuracy through numerous electroacoustic anechoic chamber measurements.

Developed the Meyer Matrix Processor, a high quality multi-channel rapid prototyping environment for the creation and real-time manipulation of digital audio signal processing systems.

Within a small core of engineers, worked on self powered speaker analog circuit design, measurement and optimization for the following products – UPA-1P, UPA-2P, USW-1P, HM-1 and HM-1S, MSL-4, 750-P, X-10, UPM-1P, UPM-2P, UM-1P, UM-100P, MSL-6, PSW-6, DF-4, M3D, MM-4.

United States Patent for the UPA-1P:

ARRAYABLE TWO-WAY LOUDSPEAKER SYSTEM AND METHOD with fellow inventors John Meyer and Paul Kohut. US006081602A

The loudspeaker system and method of the present invention is principally concerned with the polar response of a loudspeaker in the horizontal plane, and with producing a horizontal polar response from a loudspeaker system that permits two or more loudspeaker systems having overlapping coverages to be easily arrayed without undesirable interactions between the acoustic outputs of the speaker systems. The loudspeaker system and method of the invention also concerns the need to achieve a common focalpoint about which each speaker can be arrayed. As used herein, the term “focal point,” sometimes referred to as an “acoustic center,” is understood to mean that point in space about which the speaker can be rotated to achieve a flat amplitude and flat phase response. A “focal axis” is that axis about which the speaker can be rotated to achieve a flat amplitude and flat phase response in the horizonal plane. Such determinations can be made by rotating the speaker relative to a fixed microphone, or rotating a microphone about a fixed speaker.

With Paul Kohut's guidance and mentorship, I designed the active filter system for the UPA-1P. Along with many other super interesting projects, I spent a huge amount of time inside this anechoic chamber, which sits in a very unassuming shed in the parking lot of Meyer Sound on San Pablo Avenue in Berkeley California:

The chamber has a robot positioning arm which is capable of rotating heavy loudspeakers across all angles of azimuth and elevation, to a hundredth of a degree accuracy. In order to create the optimal active filter system for multiway loudspeakers, we would build the cabinets, waveguides and horns, and then measure each transducer separately, typically at 1-degree accuracy horizontally and vertically. These raw measurements would be imported into a MATLAB-based simulator to then work out the crossovers, parametric EQ filters, and allpass filters.

I also developed and maintained the Remote Monitoring Software (RMS) product and managed the product both internally and externally. I researched, implemented, and field tested an advanced large scale RMS deployment for the Tokyo Disney project, collaborating with Disney Engineering and Disney Imagineering.

I co-managed the transducer development and test group, working with both internal and external parties to specify, manufacture, test and maintain quality of all low and high frequency transducers used in production.

I worked with Solotech, Celin Dion’s sound company, to investigate and resolve the real world problems resulting in the destruction of MSL-4 high drivers through the creation and implementation of a fast acting peak limiter circuit.

Represented Meyer in AES standards committees, acting as Vice-Chair of the AESSC-SC-04-03 Subcommittee on Acoustics, Working Group on Loudspeaker Modelling and Measurement.

Represented Meyer as a technical liaison for both public and hosted events – speaking and presenting at audio conferences and seminars in North America, Europe, Australia, Asia and South America.

Developed a three-dimensional sound intensity probe utilizing a pressure sensor and three Microflown sound intensity probes – developed software acquisition and post processing system.

Performed acoustical analysis, post-processing and predictions for Carnegie Hall, system trialled and installed in 2000.

Performed acoustical analysis, post-processing and predictions for Royal Albert Hall (London, England) and Benaroya Concert Hall (Seattle, Washington, USA).

Wrote the embedded digital signal processing code for the third generation of the Meyer Sound Source Independent Measurement acoustical measurement and analysis system.

Authored and managed the creation of Meyer’s first release of acoustic data sets for the EASE electroacoustic prediction program.

Wrote numerous white papers and provided consultative review of application notes, datasheets, user manuals and other marketing materials.

Co-authored the first in-house versions of the Multipurpose Acoustic Prediction Program (MAPP) and verified its accuracy through numerous electroacoustic anechoic chamber measurements.

Developed the Meyer Matrix Processor, a high quality multi-channel rapid prototyping environment for the creation and real-time manipulation of digital audio signal processing systems.